Ruhrpumpen’s Fire Campus

NFPA 20, Standard for the Installation of Stationary Fire Pumps for Fire Protection, establishes the minimum requirements for the selection, installation, and performance of fire pump systems. When electric motors are used to drive fire pumps, NFPA 20 places strict emphasis on reliability, electrical safety, and continuity of operation during fire conditions. While NFPA 20 does not define motor voltage classes such as “medium voltage” or “high voltage,” it references voltage thresholds and defers many electrical installation requirements to NFPA 70 (NEC).

NFPA 20 permits electric motors as prime movers for fire pumps provided they are specifically listed and approved for fire pump service. The standard requires that electric motor–driven fire pumps be supplied by a reliable power source and that the electrical system be designed to minimize the possibility of interruption during a fire event. The voltage rating of the motor directly influences how the electrical supply and protection systems are designed and installed.

In practice, medium-voltage fire pump motors typically operate above 1,000 V AC and are used where pump horsepower requirements exceed the practical limits of low-voltage motors. NFPA 20 allows the use of medium-voltage motors provided the entire electrical system—including controllers, feeders, disconnecting means, and overcurrent protection—is suitable for the voltage and arranged to ensure reliable starting and operation.

NFPA 20 requires that fire pump controllers be listed for the voltage and horsepower of the motor. For medium-voltage systems, this often results in the use of reduced-voltage or across-the-line medium-voltage controllers specifically designed and listed for fire pump duty.

NFPA 20 recognizes that electric fire pump motors may be supplied from systems exceeding 1,000 V AC, but it does not provide detailed electrical installation rules for these voltages. Instead, NFPA 20 explicitly relies on NFPA 70 (NEC) for conductor sizing, insulation requirements, grounding, clearances, and disconnecting means for over-1,000-volt systems.

The intent of NFPA 20 is that high-voltage fire pump installations achieve the same or higher level of reliability as low-voltage systems, while maintaining adequate protection against fire, electrical faults, and mechanical failure.

Let us know if this information was useful for your engineering operation!

Ruhrpumpen's Spotlight

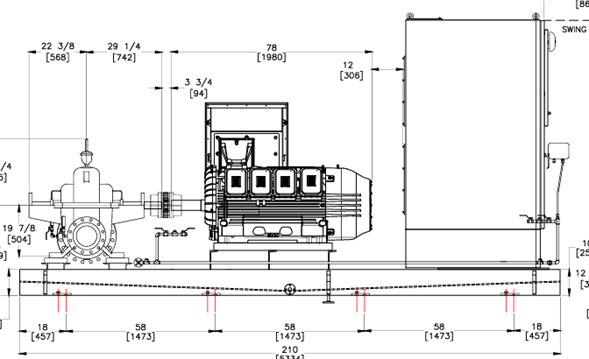

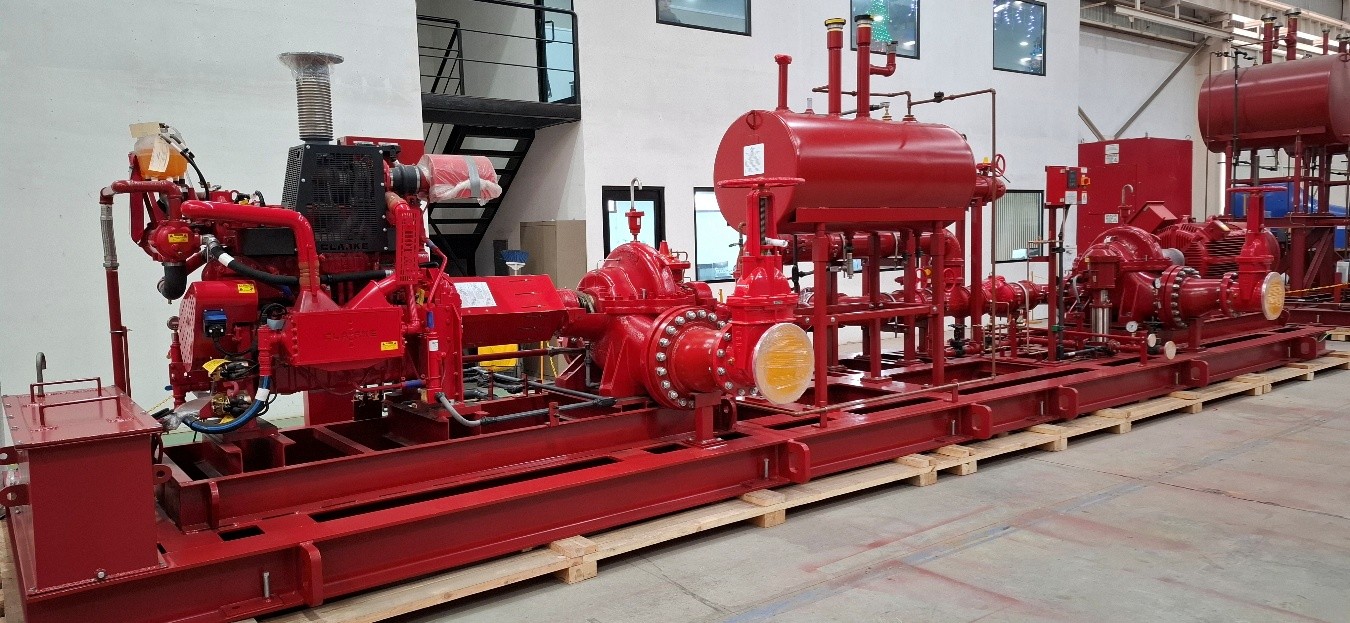

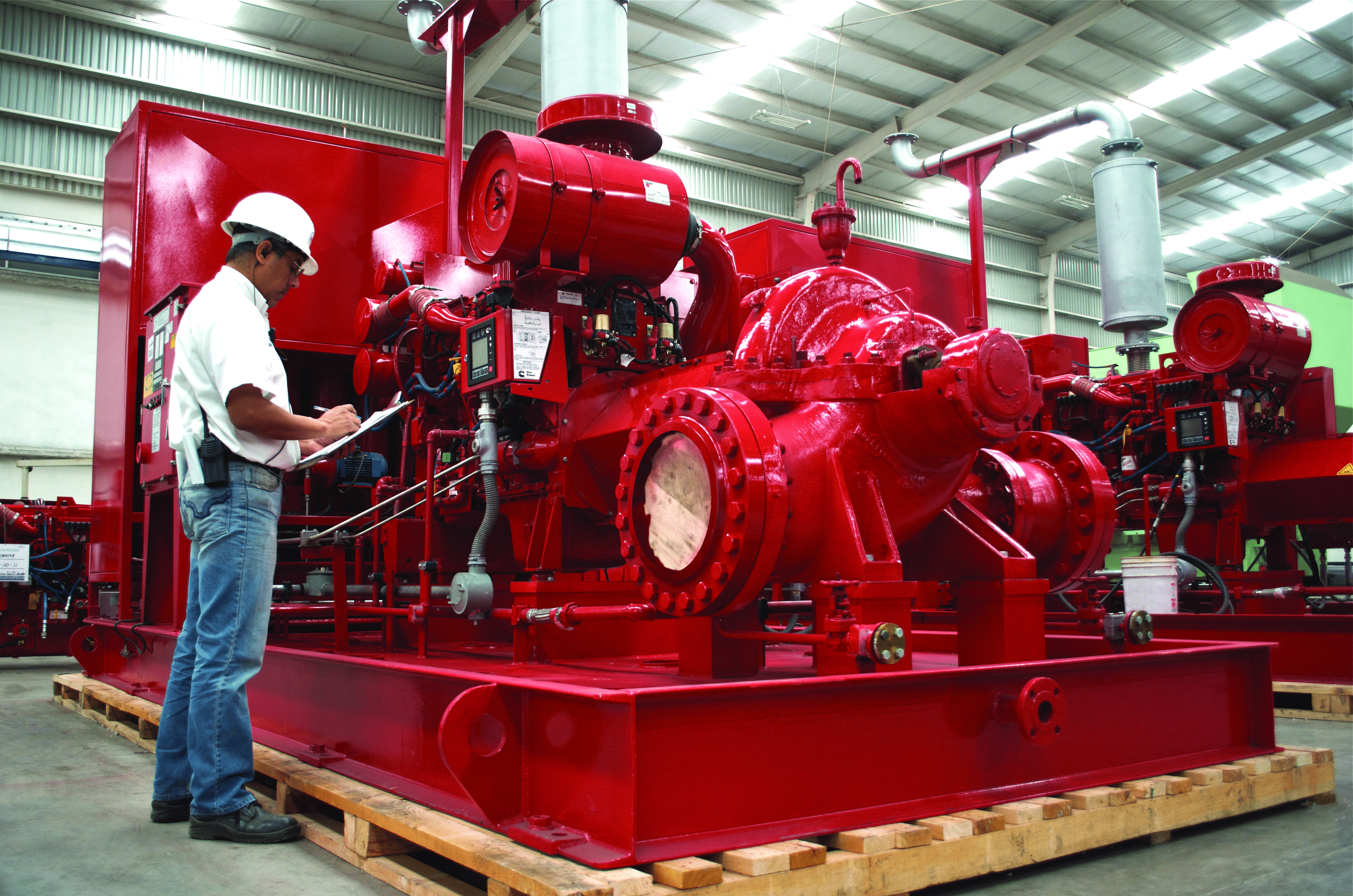

ETL-Listed fire protection system, designed in accordance with NFPA 20, integrating an electric main fire pump, a diesel main fire pump, and a jockey pump. The HSC 8×14×21E BB1-type main fire pumps are UL Listed and FM Approved, featuring a ductile iron casing, 316 stainless steel impeller, 316 stainless steel casing wear ring, and an AISI 4140 steel shaft, ensuring high mechanical reliability.

150-lb RF suction and discharge flanges, threaded drains and vents, UL/FM-listed instrumentation, and automatic air release valves are provided, fully complying with NFPA 20 requirements.

The electric drive consists of a 350 HP motor @ 1800 rpm, 4160 V, 60 Hz, three-phase, with a 1.15 service factor, Class F insulation, and Class B temperature rise. The assembly is coupled through a flexible coupling with OSHA-compliant guard and is supplied with a UL/FM-listed NEMA 4X fire pump controller, tropicalized and suitable for corrosive environments.

The diesel system incorporates a Clarke engine rated 376 HP @ 1760 rpm (Tier 3), equipped with a freshwater cooling system, residential-grade exhaust with muffler, 12 VDC electrical system, batteries, UL-listed driveshaft with guard, and a structural base. Fuel supply is provided by a UL-142 double-wall diesel tank, 250 gallons, with emergency venting and leak detection.

The vertical multistage jockey pump, designed to maintain system pressure, delivers 20 GPM @ 160 psi and is equipped with a mechanical seal, 1.5 HP TEFC electric motor, UL-Listed control panel with NEMA 4X enclosure, and dedicated instrumentation, ensuring controlled starts and overall system stability.

When every second counts, reliability isn’t optional—it’s engineered. Our 2000 GPM @ 150 psig pre‑engineered fire pump system delivers uncompromising performance through ETL‑listed integration, premium UL/FM‑approved components, and full NFPA 20 compliance.

With robust electric and diesel configurations, advanced control systems, and precision‑built pumping technology, this solution ensures your facility stays protected under the most demanding conditions. When you choose our fire protection systems, you’re not just meeting industry standards—you’re exceeding them with confidence, efficiency, and long-term peace of mind.

Protect what matters. Choose engineering that never compromises.

Are you looking for Fire Pumps and Systems to cover your pumping needs? Let Ruhrpumpen help solve your pumping demands.

Contact us now by clicking here.

Ruhrpumpen’s Fire Campus

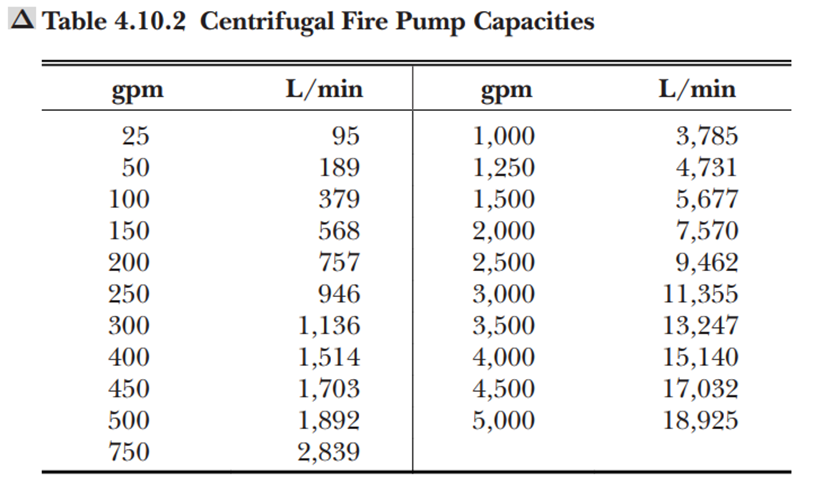

NFPA 20 Section 4.10.1 establishes a fundamental design rule that a centrifugal fire pump must be selected so that the largest single system demand does not exceed 150 percent of the pump’s rated flow. This sizing limitation exists because fire pumps are certified and tested to operate safely up to 150 percent of their rated capacity, but not beyond it. By ensuring that no connected sprinkler, monitor, hydrant, or deluge system requires more water than the pump can deliver at this upper performance limit, designers avoid conditions that would otherwise overload the pump, starve critical fire protection systems, or cause pump overheating, cavitation, or mechanical instability. For example, if the greatest fire demand is 3,000 gpm, the selected pump must be rated at least 2,000 gpm so that its 150 percent rating matches or exceeds that demand.

UL 448, the performance standard for centrifugal fire pumps, directly supports this NFPA requirement by requiring pumps to demonstrate stable, safe operation at 150 percent of their rated flow. During UL certification testing, pumps must provide at least 65 percent of rated pressure at 150 percent of rated flow while avoiding excessive vibration, overheating, or mechanical failure. Additional overload testing ensures the pump shaft, bearings, casing, and driver remain within acceptable temperature and stress limits. UL also requires stability and run-duration tests at 150 percent flow so that the pump can sustain operation at this point long enough to meet the functional needs of a fire event. These requirements confirm that pumps can safely operate at the exact limit NFPA uses as a design constraint.

FM Approval Standard 1311 contains similar performance and endurance requirements. FM requires pumps to deliver both rated flow and 150 percent of rated flow while maintaining a minimum of 65 percent of rated pressure. Pumps must also pass run testing at shutoff, 100 percent, and 150 percent capacities without overheating, exhibiting mechanical distress, or showing signs of hydraulic instability. FM adds long-duration endurance tests to verify the pump can sustain overload conditions without bearing degradation, seal failure, or fatigue cracking. These provisions reinforce the NFPA design rule by proving that approved pumps can reliably operate at the upper end of their certified performance envelope.

Together, NFPA 20, UL 448, and FM 1311 form a consistent framework: NFPA 20 dictates that system designers must limit the maximum required flow to no more than 150 percent of the pump’s rated capacity, while UL 448 and FM 1311 validate that fire pumps are physically capable of safely delivering this performance.

Ruhrpumpen's Spotlight

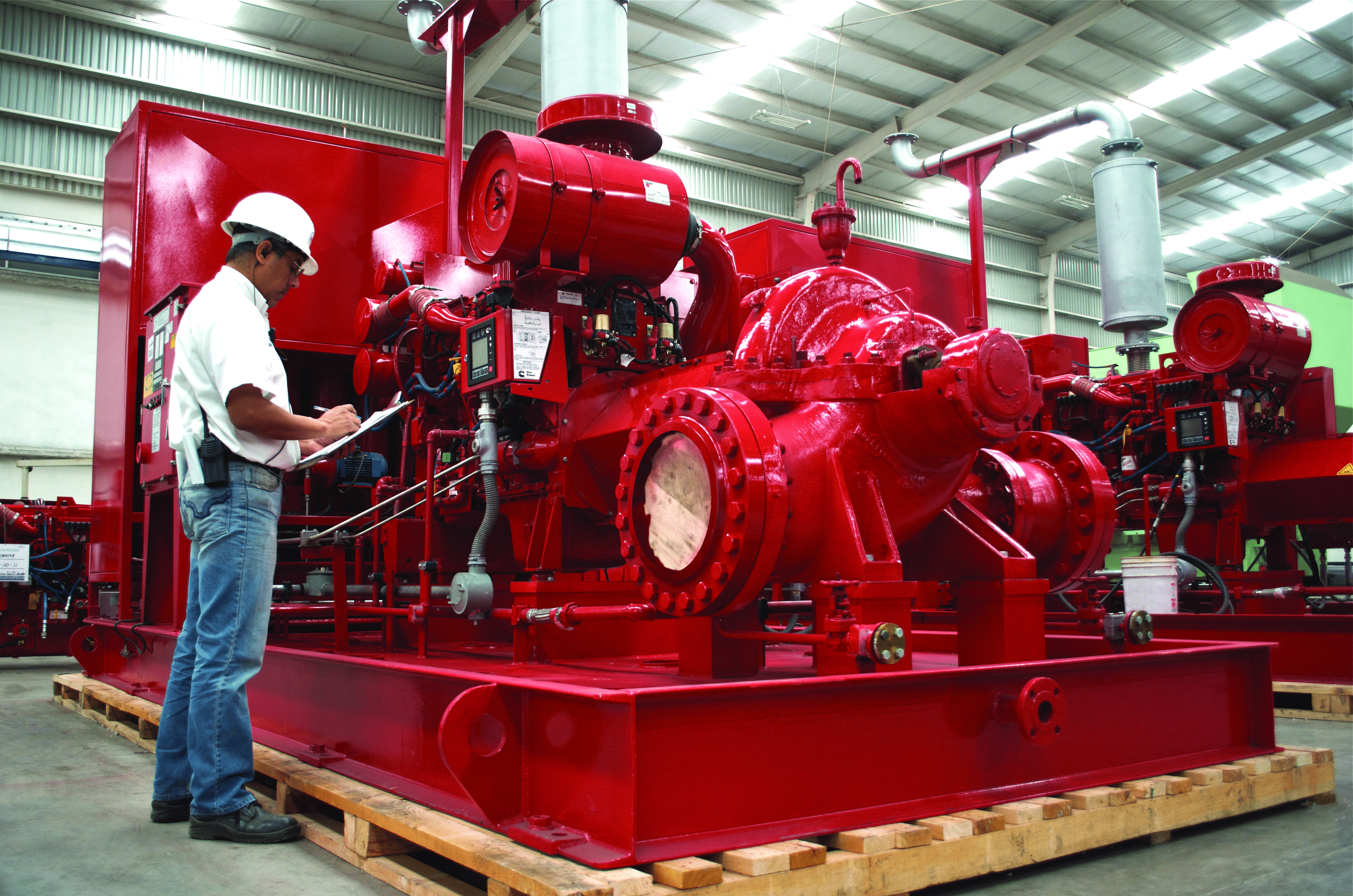

The supplied fire pump system integrates both horizontal and vertical equipment into a single, comprehensive solution designed to deliver reliable performance in critical industrial applications and high-corrosion marine environments. The main horizontal pumps are model ZW 6×5×12 (F), a BB1-type split-case unit certified UL Listed and FM Approved, offering 1500 GPM and 150 psi operating pressure. They feature a casing made of A216 WCB carbon steel, an A351 CF8M stainless steel impeller, and wear rings in Super Duplex A890 Gr. 1B, ensuring mechanical strength and long-term durability. Each pump is powered by a Clarke JU4H-UF34 diesel engine rated at 115 HP at 3000 RPM, equipped with FM-approved radiator cooling, NFPA 20 alarm and control systems, and redundant batteries for maximum availability.

Complementing these units, the system includes vertical turbine pumps model 20C-600, VS1 type, fully manufactured in Duplex stainless steel to withstand seawater and corrosive conditions. These pumps feature two hydraulic stages, 20-inch bowls, 12-inch flanged column with a total length of 10.58 feet, and Duplex shafts lubricated by product. They are driven by Clarke DS0H-UFAA68 diesel engines rated at 587 HP at 1760 RPM, equipped with FM-approved marine cooling loops, 316 stainless steel silencers and spark arrestors, tropicalized control systems, and 24-V NiCd battery banks. The package also includes reinforced marine gearheads, corrosion-protected drive shafts, and Super Duplex accessories that ensure reliable performance even under harsh marine exposure.

The scope also includes a vertical auxiliary pump model 6A-6 with six stages, entirely built in Duplex, featuring a 4-inch flanged column, a 1-inch shaft, and a 4” 150# RF spool piece. This pump is powered by a 20 HP, 3600 RPM, VHS TEFC IP56 electric motor with Class H insulation, suitable for continuous duty in demanding environments. To maintain system pressure, a multistage jockey pump model WDM/VSE 10-10-100 is included, delivering 62 GPM at 142 psi and driven by a 10 HP, 440-V motor. It is complemented by a UL/FM Cla-Val 55L pressure relief valve to ensure stable operation across the network.

All equipment is controlled by advanced UL/FM-certified controllers. The main pumps are equipped with Tornatech GPD controllers housed in NEMA 4X stainless steel enclosures, featuring NiCd battery chargers, full NFPA 20 alarm packages, Modbus remote monitoring capability, and protection features tailored for marine environments. The jockey pump is managed by a Tornatech JPLT controller with a ViZiTouch interface and protections against phase failure, overload, and unsuccessful starts. The system also includes double-wall UL-142 diesel tanks, certified leak sensors, 316 stainless steel flame arresters, Super Duplex Cla-Val valves and strainers, and Rosemount 2051G instrumentation built with corrosion-resistant alloys. All pumps are supplied on common bases coated with C5-M marine-grade protective paint for maximum durability in severe environments.

The result is an integrated fire pump solution that combines flow, pressure, hydraulic efficiency, and superior corrosion resistance, supported by mission-critical diesel engines and certified controllers. This system provides a robust and reliable platform designed to ensure operational continuity in industrial facilities where fire protection is a strategic priority.

Are you looking for Fire Pumps and Systems to cover your pumping needs? Let Ruhrpumpen help solve your pumping demands.

Contact us now by clicking here.

Discover fully engineered systems that deliver performance, reliability, and peace of mind, all from a single source supplier.

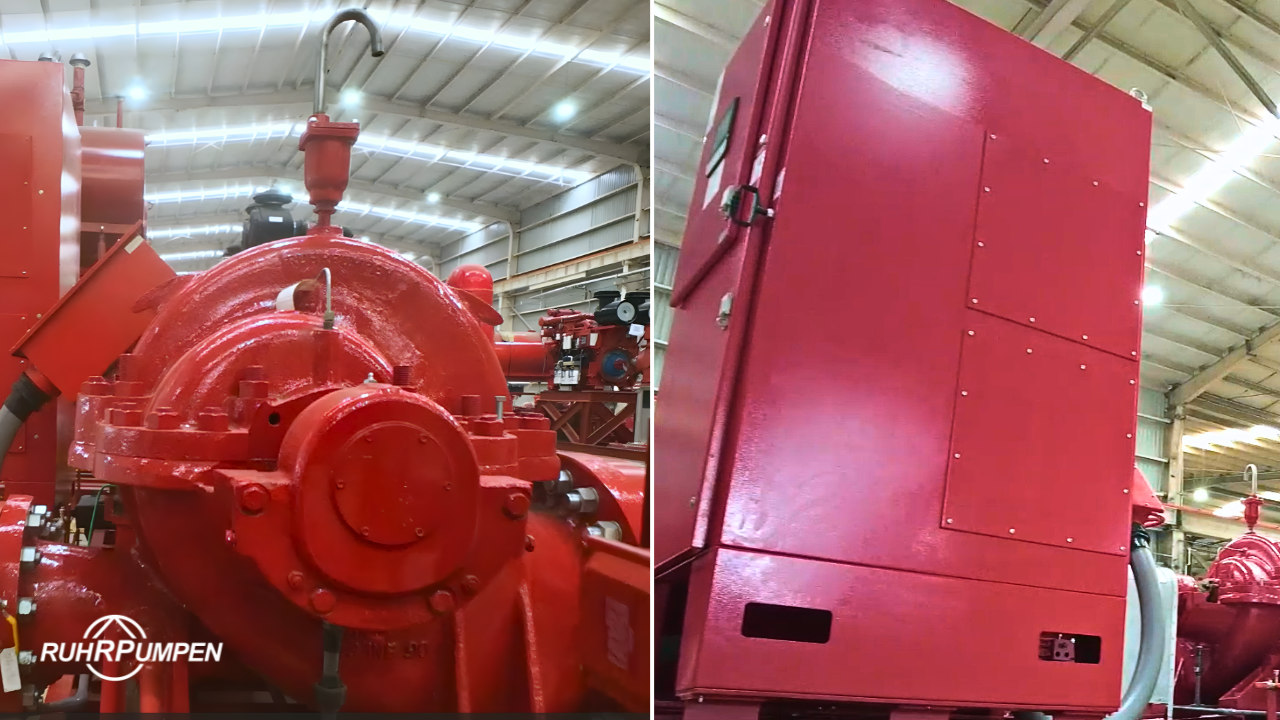

Following the successful delivery of a complete system for a major gas project in Peru, Ruhrpumpen has once again proven its capability to design and supply integrated solutions tailored for hydrocarbon and water handling applications.

We go beyond individual pumps, we design and deliver complete engineered systems that integrate performance, reliability, and efficiency from start to finish.

Following the successful delivery of an engineered system for a major gas generation project in Peru, Ruhrpumpen has now provided an additional package of equipment designed for hydrocarbon and water handling applications.

This project includes the supply of RDPT pumps (16 m³/h, 86 kW) and SCE pumps (26 m³/h, 20.41 kW), systems specifically engineered to support separation processes and ensure safe, continuous production under demanding operating conditions.

The final system verification was successfully completed in the presence of the client, reaffirming the quality, performance, and reliability that define Ruhrpumpen’s engineered solutions.

Watch the whole video by clicking here: Youtube Video

Our new offices in Monterrey represent growth, innovation, and the spirit that drives Ruhrpumpen forward.

During the summer of 2025, Ruhrpumpen proudly relocated its corporate office to the modern BH LifeWork building, located in Monterrey, Nuevo León, Mexico.

Monterrey is not only our hometown — it is also one of the most important industrial hubs in Latin America. Known for its solid infrastructure, highly skilled talent, and relentless drive for innovation, this city perfectly embodies the spirit of Ruhrpumpen: hard work, global vision, and an enduring commitment to excellence.

Our new home reflects that same commitment. It is a space designed to foster collaboration, enhance efficiency, and elevate the overall experience — a place that inspires us to continue developing pumping solutions that move the world.

This move represents more than a change of address. It’s a natural step in our evolution and a reaffirmation of who we are: a global team united by shared passion and purpose.

Watch the whole video by clicking here: Youtube Video