Three Codes and Standards for Comprehensive Safety

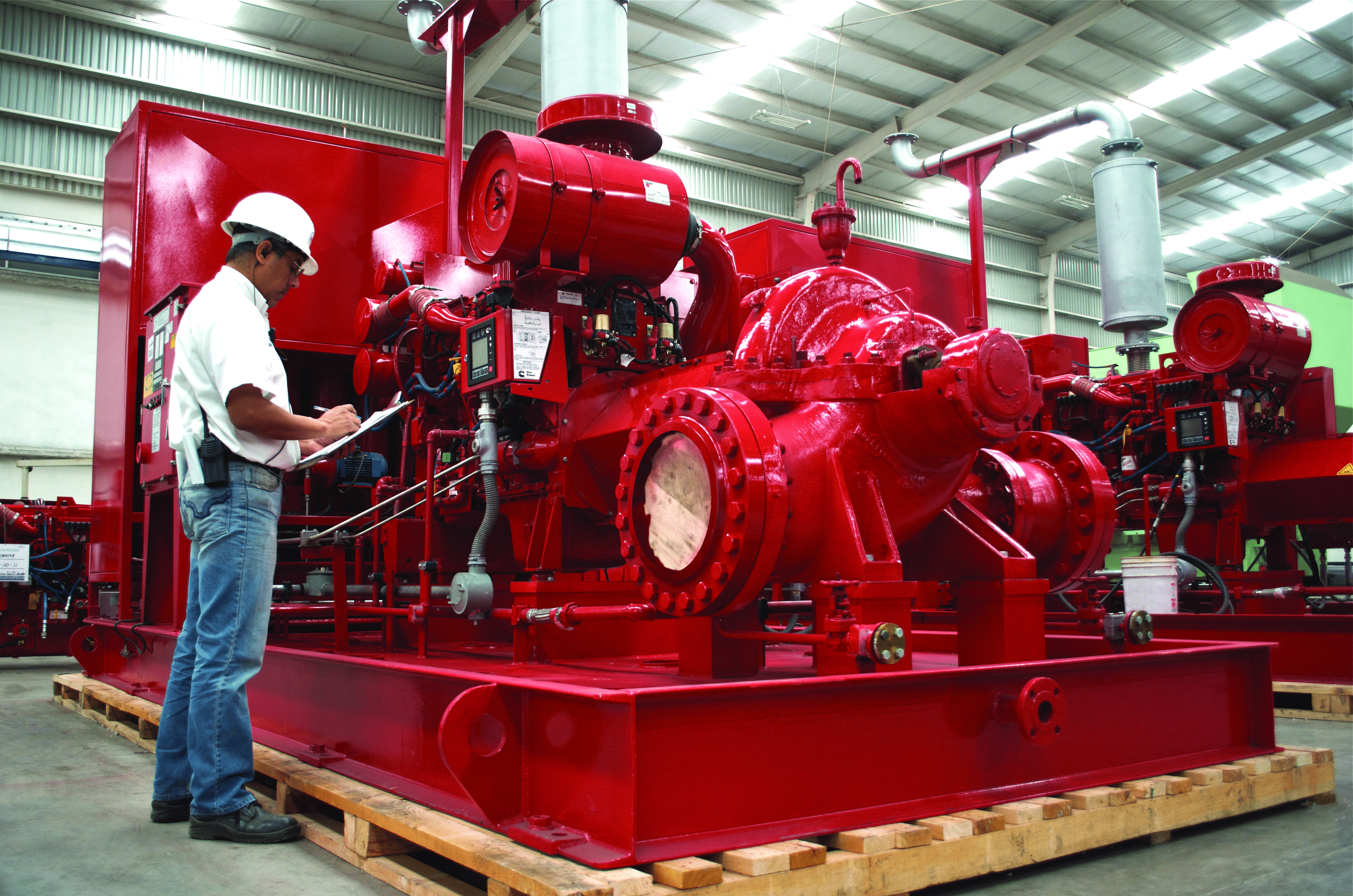

Ruhrpumpen's Fire Campus: March 2025

Electrical safety is a critical responsibility for everyone involved in the design, installation, and maintenance of electrical systems. NFPA offers knowledge and training resources on three essential codes and standards—known as the Electrical Cycle of Safety™ (ECoS™)—to help ensure a safe, reliable, and effective approach to achieving comprehensive electrical safety.

When used collectively, these codes complete the Electrical Cycle of Safety. Where just one is missing, it could result in preventable incidents that put people, property, and critical processes at risk.

Let's see them one by one:

Install with NFPA 70 (NEC).

NFPA 70®, National Electrical Code® (NEC®): The benchmark for electrical design and installation for residential, commercial, and industrial applications. The NEC is updated every three years—staying in sync with industry practices, emerging trends, and the development and introduction of new technologies—and sets the foundation for safe electrical design and installation to help protect people and property from electrical hazards.

Maintain with NFPA 70B

NFPA 70B, Standard for Electrical Equipment Maintenance: Details preventive maintenance for electrical, electronic, and communications systems and equipment. NFPA 70B helps prevent electrical failures and contributes to electrical safety with guidance on establishing a condition of maintenance for electrical equipment and systems, which is required by NFPA 70E. When businesses apply the requirements in NFPA 70B—in conjunction with those in the NEC and NFPA 70E—they can help avoid preventable downtime of key electrical equipment, systems, and core processes, all while helping to ensure employees stay safe.

Protect with NFPA 70E

NFPA 70E®, Standard for Electrical Safety in the Workplace®: Provides safe work practices to help protect employees by reducing exposure to electrical risks. NFPA 70E is a key asset in helping to prevent injuries and assisting in safeguarding employees by working to mitigate hazards like shock, arc flash, and electrical fires. NFPA 70B and NFPA 70E are particularly interconnected through the "condition of maintenance" requirement in both, since electrical equipment that isn’t well maintained poses safety risks to employees and, in some cases, even the public.

Ensuring electrical safety is a fundamental responsibility that must be prioritized at every stage of an electrical system’s lifecycle, from initial design and installation to ongoing maintenance and operational procedures. The Electrical Cycle of Safety™ (ECoS™), which incorporates NFPA 70, NFPA 70B, and NFPA 70E, provides a comprehensive framework to safeguard both people and property from electrical hazards, as we mentioned above. These standards work together to establish a robust system of electrical safety, where each code plays a vital role in achieving a safe and reliable electrical environment.

By applying these standards collectively, organizations can create a safe work environment, ensuring that electrical systems are not only functioning properly but are also well-maintained and free from hazards that could harm employees, disrupt operations, or cause significant property damage. It highlights the importance of ongoing attention to electrical systems to prevent safety incidents. Ultimately, the commitment to following these codes leads to a more resilient, efficient, and secure workplace, safeguarding employees, critical processes, and infrastructure from preventable electrical risks.

Did you know Ruhrpumpen is a proud NFPA member?

As per NFPA-20, each pump is tested at our manufacturing facilities to provide detailed performance data and to demonstrate its compliance with the required specifications.

Download the Fire Systems Brochure to find more details of our pumps and systems.