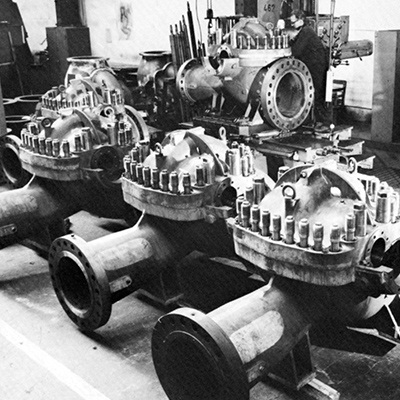

Ruhrpumpen GmbH in the 1950s

Our history started simultaneously in Germany and in Mexico. In Germany, Ruhrpumpen GmbH Wende & Hentschel started as a small pump operation doing maintenance to the installed pumps from all makers and models, as well as manufacturing spare parts.

In the same year, in Mexico, Worthington de México was incorporated as a pump manufacturing plant, serving mainly the water markets in the country. Both companies continued their growth path independently and went through several changes of ownership during the years.

1979

Maquinados Programados was formed in Monterrey, Mexico to provide machining services to domestic Original Equipment Manufacturers (OEMs). Since its formation, state-of-the-art machining technology was the base, being the first independent CNC machine shop in the northern Mexico.

It grew very rapidly until 1982, when Corporación EG faced the first oil crisis. Maquinados Programados participated in different industries and continued its growth after a couple of years of tough times.

1986

Through the vision of the Elizondo Garza family, we capitalized the opportunity to become an OEM in 1986. The company acquired the assets of an established pump company named Crane Deming de México located in Monterrey, this move opened the door to become an OEM in the pump market in Mexico.

When it was acquired, the company had a very limited product portfolio. This demanded an entrepreneurial spirit to develop and be competitive through new product lines and state of the art manufacturing technology.

1988

One of the biggest challenges for Maquinados Programados and Crane Deming de México was the availability of competitive and quality castings. RP Metals was born, a no-bake foundry for a low-mid volume steel and Cast-Iron castings, using induction furnaces according to our pump needs.

Our own foundry enabled us to have control of our castings supply chain, improve our quality and delivery.

1991

Crane Deming de México acquired the assets of Worthington de México. After a couple of months relocated the plant from Mexico City to Monterrey and merged it with the existing pump operation.

This acquisition increased substantially our product portfolio, markets and regions served with a 40-year-old installed base.

1993

The North American Free Trade Agreement (NAFTA) was signed; Derlan Industries from Canada formed a joint venture with Maquinados Programados. This was the inception of Corporación EG.

The join venture came with new challenges and opportunities that had to be faced, the implementation of best practices of an International company had to be deployed, establishment of Company Board and compliance with the most demanding stake holders. But also, access to new manufacturing technology, markets and international growth possibilities.

1996

While looking for a pump company that could license us the technology to manufacture large submersible sewage pumps; we found a very well-known brand name in Europe, Ruhrpumpen GmbH. This new acquisition came with a fantastic group of talented people, new technologies mainly for the oil and gas industry, an established European and Southeast Asia customer base, large manufacturing facilities, and the ability to test pumps up to 10,000 HP. Acquiring Ruhrpumpen became a major milestone for Corporación EG.

The New Ruhrpumpen

Acquisition of Ruhrpumpen GmbH by Corporacion EG, 1997

In 1997, Mr. Cesar A. Elizondo Villarreal, founder of the Mexican family company Corporación EG, together with his Canadian financial partners, acquired Ruhrpumpen GmbH. With this, Mr. Elizondo became the first Mexican entrepreneur ever to invest in a German industrial undertaking.

Corporacion EG was a successful company with strong reputation for quality and operational excellence that began operations in 1979 as a Computer Numeric Control (CNC) machine shop in Monterrey, Mexico, to render services to Original Equipment Manufacturers (OEMs). In 1986, the firm acquired its first pump company, Crane Deming de Mexico SA de CV, and went on to take over Worthington de Mexico SA de CV in 1991.

Since 1997, a series of capital investments, acquisitions, new product development and a strong focus on customer needs have taken Ruhrpumpen to become a global supplier of highly engineered pumping technologies and related products:

2000

After a merge of the 2 largest players in the API market, Corporación EG had the great opportunity to acquire the ex-Byron Jackson facility located in Tulsa, Oklahoma. At the time, we had a limited presence in the US market, so it was a big step into the world’s biggest pump market. We decided to call it Ruhrpumpen Inc.

With this acquisition a group of very talented people, a large manufacturing plant and 8 API Product lines with a global installed base increased our API portfolio becoming a solid API competitor in the global market.

The time came to start with the consolidation of our pump businesses (Worthington de México, Ruhrpumpen Inc., and Ruhrpumpen GmbH).

With the alignment of the best resources into the best opportunities, the first step was to form an independent global sales force from the pump operations.

Worthington de México became Ruhrpumpen S.A. This marked the beginning of what today is the Ruhrpumpen Group.

2001

With the intent to expand our product portfolio and be a more value-added supplier for our customers, a strategic decision was made to enter the decoking systems niche in the oil and gas industry.

Our 1st complete decoking system for a refinery was quoted for Venezuela and won the order for Hamaca Project. At the time, we had no experience in decoking systems neither drawings, with a strong German Engineering team the engineering and design process started. In the end, Ruhrpumpen successfully supplied the system series 001. Today we are a major player in the global decoking business, leading on technology and performance.

2004

The customer base started to demand a more local presence with national integration, support and competitive service. This triggered an organic growth and expansion of Ruhrpumpen global footprint.

Ruhrpumpen Argentina was formed, to provide pumping systems and services in the South Cone.

2006

The rapid organic growth continued. An opportunity to form a joint venture with the Egyptian government came and led to the formation of Ruhrpumpen Egypt for the production and service of API centrifugal pumps for the domestic market.

2007

Birth of the Fire Pumps Business Unit, Ruhrpumpen Systems.

2009

To serve the growing Indian market and consolidate operations in the Middle East and Southeast Asia, the company established a new manufacturing facility, Ruhrpumpen India.

To support the growth, aligning the best resources to the best opportunities to improve capacities and capabilities, the decision was taken to realign the original CNC machining business as well as the foundry to our pump group.

Besides having a full control of the supply chain, Maquinados Programados became Ruhrpumpen Industrial, and the foundry changed the focus to dedicate the resources producing castings only for the Ruhrpumpen Group, today this is Ruhrpumpen Metals.

2010

Fire Fighting systems have been part of our product portfolio for many years, a demand for a reliable and competitive supplier was identified.

In order to capitalize this opportunity, we had to be focused and specialized, we spun-off the fire systems business from RPSA. An independent business unit was formed to serve the market for both commercial and industrial applications. Today, Ruhrpumpen Systems has complete UL and FM approved pump lines, with an important presence in many parts of the globe.

2011

With the largest population in South America, Brazil has great oil reserves, a protected market with a forecast of a large infrastructure needs.

It was the right time to reinforce our presence in the country with the opening of a new state-of-the-art manufacturing facility, Ruhrpumpen Brazil.

2012

Ruhrpumpen expands its presence in the emerging markets with the opening of a new modern manufacturing facility in Changzhou, China.

New Plant - RP Argentina.

2013

Ruhrpumpen expands its global service network by opening a new Service Center in Antofagasta, Chile, to attend its customers in the South Cone.

2014

Ruhrpumpen has always had a very good reputation in the Chinese market being the leader in pipeline applications.

The time came to invest and have our own manufacturing facility in China. Ruhrpumpen China was opened, a new modern manufacturing facility.

2015 - 2016

Our first non-centrifugal pump line was added with the addition of Ruhrpumpen UK, established and focused on design and manufacture of API plunger pumps mainly but not limited for the oil and gas markets.

2019

Ruhrpumpen Industrial Europa was setup in the UK as the starting point for our entry into the European industrial pump market.

With the expansion of our industrial products, the development of a strong and competitive supply chain, forms the basis of Ruhrpumpen Industrial's expansion.