Based on the worldwide proven hydraulic design of the SCE model, the SCE-M is a sealless centrifugal pump, 100% leakage free, avoiding high maintenance costs and usage of mechanical seals. It is the best option for heavy chemical handling applications, in completion to API 610 pumps for the majority of applications in the pretrochemical industry and refineries.

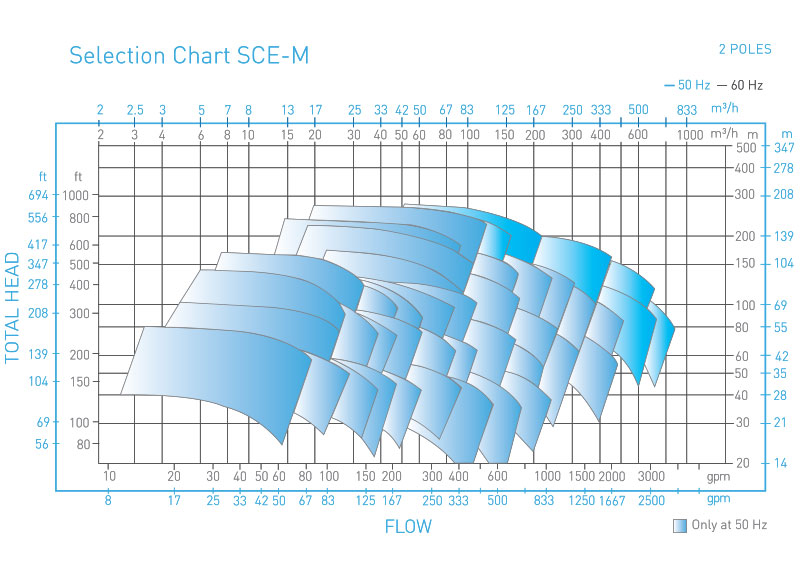

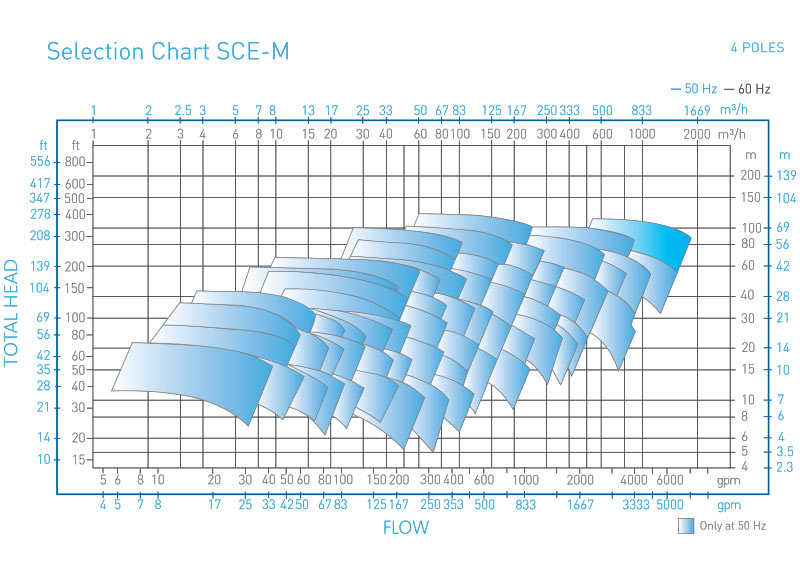

With over 130 hydraulic combinations available for the SCE-M pump, almost all customer requirements are met. To enhance performance and optimize efficiencies, the SCE-M counts with three different impellers for each pump size. It is built with the latest engineering techniques and tools such as 3D modelling and Finite Element Analyis to assure the best product quality.

CHARACTERISTICS

- Horizontal, overhung, single stage

- Radially split

- Centerline mounted casing

- End-Top nozzle arrangement

- Single suction impeller

- Axial thrust balance

- Sealless, no mechanical seal

CONSTRUCTION MATERIALS

- Materials of construction per API 685 (other materials on request)

DESIGN FEATURES

Heavy-duty process design according to API 685 latest edition

- Ring Oil Lubrication (other methods available)

- Replaceable front and back wear rings for casing and impeller

- Patented Journal Bearing design (made of silicon carbide (SSiC))

- Inducers for low NPSH available

- Ceramic insulation and thermal barrier

- 100% leakage free containment shell, self vented and fully drainable

BENEFITS

- Environmentally friendly - Zero fugitive emissions to the atmosphere

- Directly interchangeable with other dimensional standard pumps

- Maximum bearing life given that there are no bearing alignment problems

- Cost savings through optimum efficiency

By eliminating leakage and removing unreliable seals from the design, Ruhrpumpen Sealless Magnetic Drive Pumps have a positive environmental impact and improve industrial safety over traditional sealed designs.

CRP-M Mag Drive Process Pump

CRP-M Mag Drive Process Pump CRP-M-CC Mag Drive Process Pump

CRP-M-CC Mag Drive Process Pump