Ruhrpumpen’s cryogenic VLT pump is the development of years of experience in cryogenic service and considers the unique engineering challenges associated with low temperature, cryogenic pumping. These pumps are used both stand-by and continuous service.

The pump is designed to mount in a “cold box” so that all of the low temperature portions of the unit can be insulated. It is normally driven by a vertical solid shaft electric motor that is designed to carry the hydraulic thrust developed by the pump through grease lubricated anti-friction bearings.

CHARACTERISTICS

- Low NSPH "Shockless Entry" first stage impeller

- Double suction first stage available

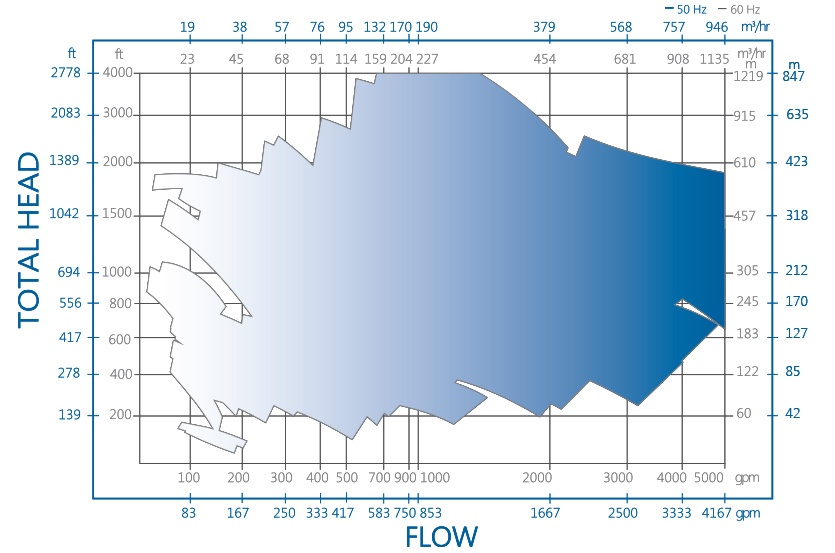

- Over 700 vertical Ruhrpumpen pump hydraulics can be used for construction

- Integral fabricated column support bearings

- Rigid 4-piece coupling

- Single or Double Suction first stage

- Single Stage or Multistage available

- Nozzles are available with the suction in the head or barrel

DESIGN FEATURES

- Vertical construction designed for mounting in an insulated “cold box” for immediate and ready start up

- Special first stage impeller with low NPSH requirement characteristics to keep pump length to a minimum

- Simple thermal isolation of sealing area requiring no heaters or special temperature controls

- Simple sealing systems for isolating gaseous product from atmosphere

- Provision for monitoring sealing performance

- Conventional vertical solid shaft motor utilizing grease lubricated anti-friction bearings with long minimum bearing life