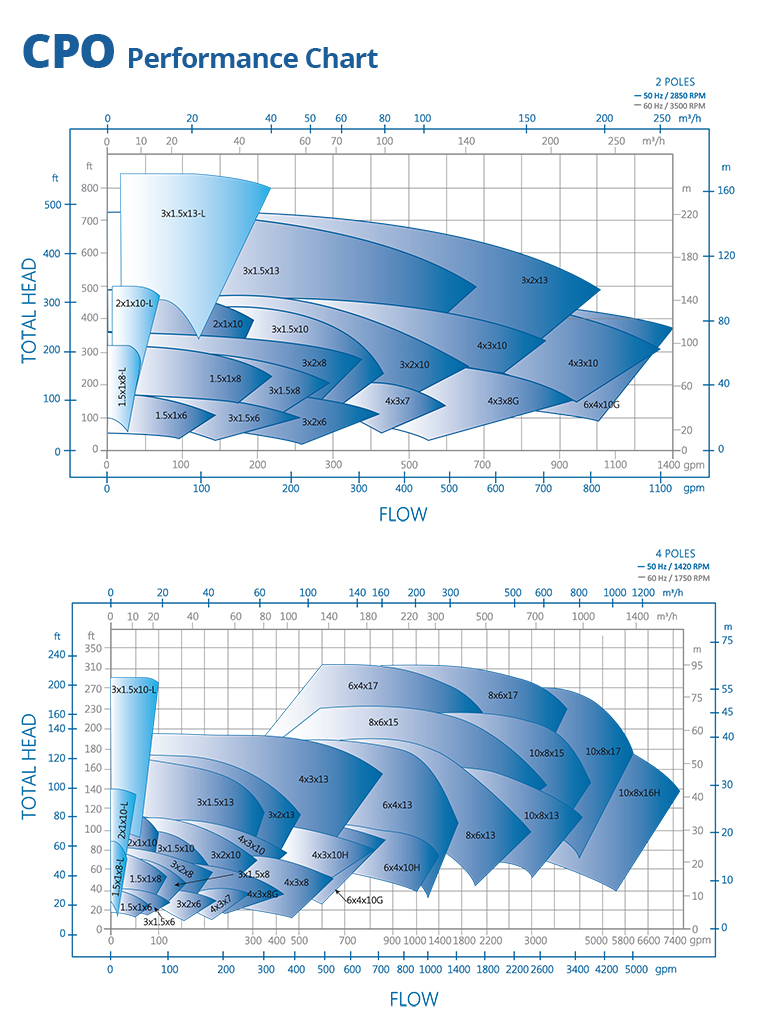

With +30 hydraulics, the CPO pump line is designed to meet and exceed the ANSI/ASME B73.1 specification. Its open impeller design covers a wide range of service conditions (including a low flow region with our CPO-L model) while providing industry-leading low NPSHR performance and high efficiencies.

The CPO pump is designed around a modular concept which allows the provision of multiple hydraulics with a small number of Power Frames. In addition, these Power Frames are completely interchangeable with models of other common ANSI pump manufacturers.

CHARACTERISTICS

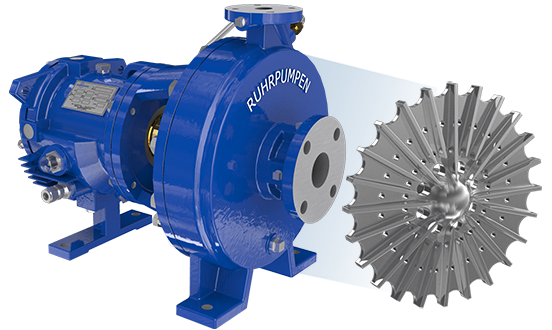

Designed to meet your most difficult applications with a state-of-the-art open impeller, CD4MCu wetted parts as standard and a heavy-duty Power Frame.

- Horizontal, overhung, single stage, end suction ANSI process pump

- Foot mounted, back pull-out design for ease of maintenance

- Dimensional interchangeability with most common ANSI/ASME B73.1 pump manufacturers

- Open impeller design allows handling of solids in suspension. The impellers are locked onto the shaft by threads and sealed with an O-ring

- External impeller adjustment sets impeller quickly and accurately without the need for special tools

- Machined flat surface suitable for use with magnetic mount vibration probe

- Double row, angular contact thrust bearings minimize axial shaft end-play thus maximizing mechanical seal life

- A robust solid shaft with outstanding L3/ D4 for low vibration and increased mechanical seal life (shaft sleeves are available as an option)

- INPRO VB45-STM labyrinth bearing isolators to avoid bearing contamination

- Lubrication:

- Oil bath lubrication as standard, with option for grease and oil mist lubrication

- Large capacity oil sump and finned housing provide superior cooling

- Optional finned oil cooler

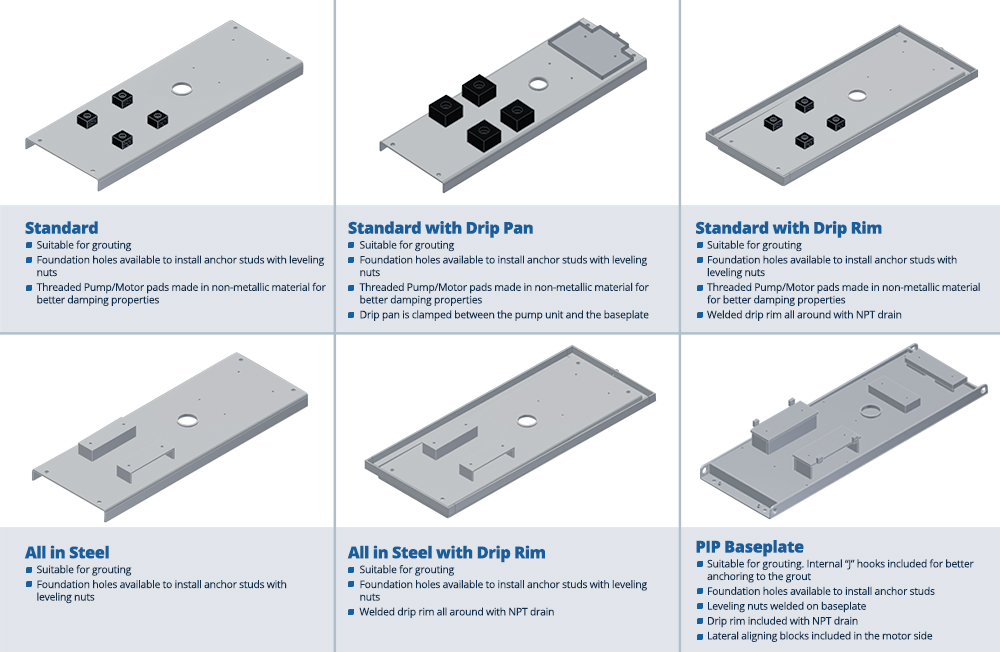

OPTIONAL FEATURES

- C-Frame motor adapter

- Different baseplate mounting systems

- Sealing

- Large taper bore with flow modifiers

- Standard large and small bore

- Cooling coil to maintain proper oil temperature in hot applications

CONSTRUCTION MATERIALS

Materials in stock:

- DI / SST

- DI / Duplex

- SST / SST

- Duplex / Duplex

Special materials:

- Alloy 20

- Hastelloy B and C

- Zirconium

- Titanium

Other materials on request