Ruhrpumpen´s Spotlight

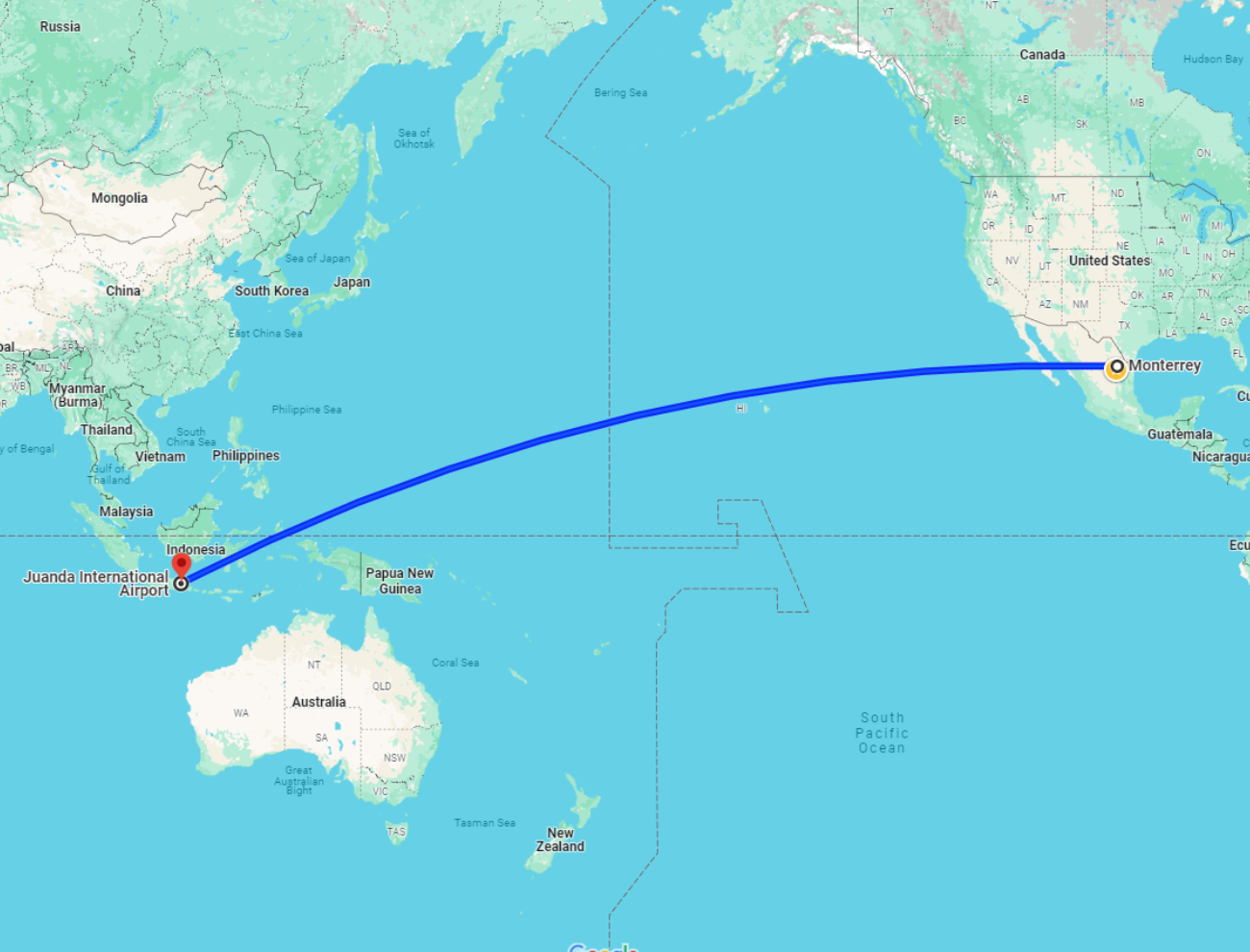

Cutting-Edge Pump House Solution for a Jakarta Refinery

Ruhrpumpen has recently delivered a cutting-edge ETL Listed prepackaged pump house to a refinery in Jakarta, designed to meet the fire protection requirements of the oil and gas sector. The pump house includes both electric and diesel engine-driven fire pumps, along with a jockey pump, ensuring robust fire suppression capabilities. The system is housed in a compact unit measuring 8’-2” wide x 40’-0” long x 11’-0” high, featuring a durable shed-style roof and fully insulated walls and roof for efficient thermal management.

The electric set in this installation comprises a Horizontal Split Case pump constructed from cast iron and stainless steel, driven by a 185 kW motor operating at 3000 RPM. The motor is designed to IEC standards, featuring Totally Enclosed Fan Cooled (TEFC) construction with IE3 efficiency, and is controlled by a Tornatech GPA controller housed in a NEMA 2 enclosure. This configuration ensures reliable performance and compliance with industry efficiency and safety standards.

Complementing the electric set is a diesel-driven Horizontal Split Case pump, also made from cast iron and stainless steel, with a JU6H-UF94 motor delivering 300 hp at 3000 RPM. The diesel engine meets emission standards, reflecting an emphasis on environmental considerations alongside operational efficiency. Control is managed by a Tornatech GPD controller, ensuring seamless integration with the system’s safety protocols.

The jockey pump, an essential component for maintaining system pressure, is an End Suction model made from ductile iron, driven by a 30 kW motor at 3000 RPM. It features TEFC construction, controlled by a Tornatech JP3 controller. This setup is crucial for the system's readiness, maintaining pressure and ensuring immediate response in the event of a fire.

The pump house is meticulously designed for operational efficiency and ease of maintenance, incorporating Ruhrpumpen’s standard fuel supply lines, electrical interconnections, and sensing lines. It includes essential features such as resilient OS&Y Gate valves, discharge butterfly isolation valves with tamper switches, and a pump house sprinkler system compliant with NFPA 13 standards. This comprehensive solution underscores Ruhrpumpen’s commitment to providing reliable, high-performance fire protection systems tailored to the needs of critical infrastructure in the oil and gas industry.