Reliable Fire Protection: Ruhrpumpen Split-Case and Vertical Turbine Pump Integration

Ruhrpumpen's Spotlight

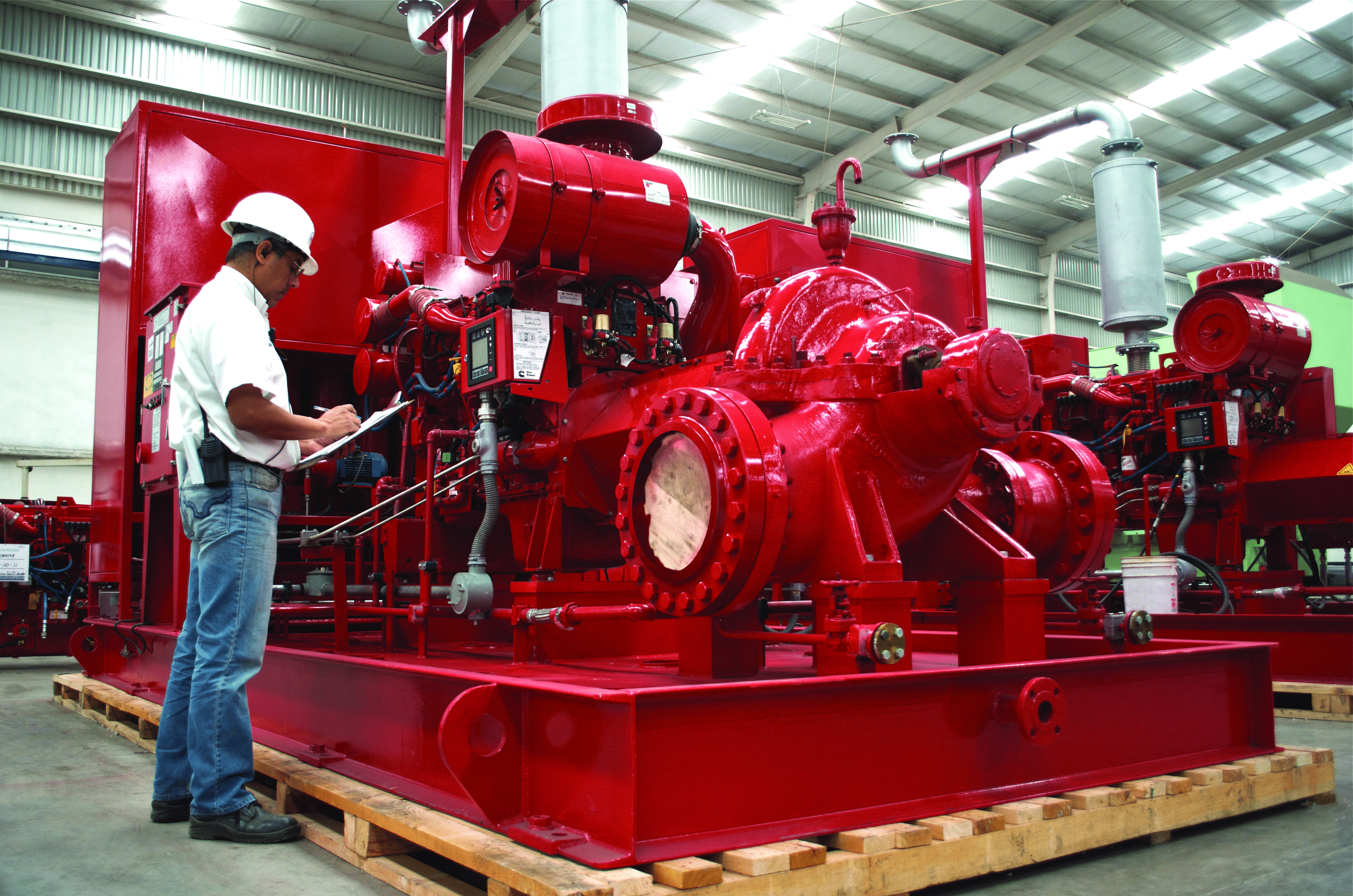

The supplied fire pump system integrates both horizontal and vertical equipment into a single, comprehensive solution designed to deliver reliable performance in critical industrial applications and high-corrosion marine environments. The main horizontal pumps are model ZW 6×5×12 (F), a BB1-type split-case unit certified UL Listed and FM Approved, offering 1500 GPM and 150 psi operating pressure. They feature a casing made of A216 WCB carbon steel, an A351 CF8M stainless steel impeller, and wear rings in Super Duplex A890 Gr. 1B, ensuring mechanical strength and long-term durability. Each pump is powered by a Clarke JU4H-UF34 diesel engine rated at 115 HP at 3000 RPM, equipped with FM-approved radiator cooling, NFPA 20 alarm and control systems, and redundant batteries for maximum availability.

Complementing these units, the system includes vertical turbine pumps model 20C-600, VS1 type, fully manufactured in Duplex stainless steel to withstand seawater and corrosive conditions. These pumps feature two hydraulic stages, 20-inch bowls, 12-inch flanged column with a total length of 10.58 feet, and Duplex shafts lubricated by product. They are driven by Clarke DS0H-UFAA68 diesel engines rated at 587 HP at 1760 RPM, equipped with FM-approved marine cooling loops, 316 stainless steel silencers and spark arrestors, tropicalized control systems, and 24-V NiCd battery banks. The package also includes reinforced marine gearheads, corrosion-protected drive shafts, and Super Duplex accessories that ensure reliable performance even under harsh marine exposure.

The scope also includes a vertical auxiliary pump model 6A-6 with six stages, entirely built in Duplex, featuring a 4-inch flanged column, a 1-inch shaft, and a 4” 150# RF spool piece. This pump is powered by a 20 HP, 3600 RPM, VHS TEFC IP56 electric motor with Class H insulation, suitable for continuous duty in demanding environments. To maintain system pressure, a multistage jockey pump model WDM/VSE 10-10-100 is included, delivering 62 GPM at 142 psi and driven by a 10 HP, 440-V motor. It is complemented by a UL/FM Cla-Val 55L pressure relief valve to ensure stable operation across the network.

All equipment is controlled by advanced UL/FM-certified controllers. The main pumps are equipped with Tornatech GPD controllers housed in NEMA 4X stainless steel enclosures, featuring NiCd battery chargers, full NFPA 20 alarm packages, Modbus remote monitoring capability, and protection features tailored for marine environments. The jockey pump is managed by a Tornatech JPLT controller with a ViZiTouch interface and protections against phase failure, overload, and unsuccessful starts. The system also includes double-wall UL-142 diesel tanks, certified leak sensors, 316 stainless steel flame arresters, Super Duplex Cla-Val valves and strainers, and Rosemount 2051G instrumentation built with corrosion-resistant alloys. All pumps are supplied on common bases coated with C5-M marine-grade protective paint for maximum durability in severe environments.

The result is an integrated fire pump solution that combines flow, pressure, hydraulic efficiency, and superior corrosion resistance, supported by mission-critical diesel engines and certified controllers. This system provides a robust and reliable platform designed to ensure operational continuity in industrial facilities where fire protection is a strategic priority.

Are you looking for Fire Pumps and Systems to cover your pumping needs? Let Ruhrpumpen help solve your pumping demands.

Contact us now by clicking here.