Why NFPA 20 Limits Fire Pump Flow to 150% of Rated Capacity

Ruhrpumpen’s Fire Campus

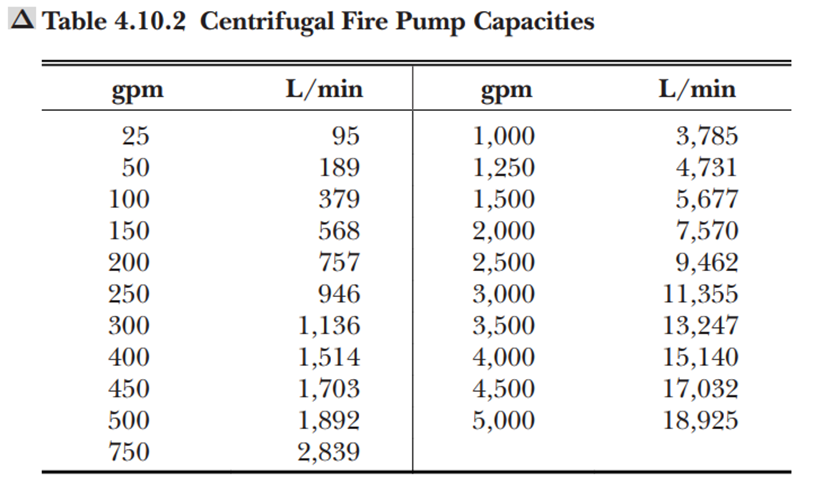

NFPA 20 Section 4.10.1 establishes a fundamental design rule that a centrifugal fire pump must be selected so that the largest single system demand does not exceed 150 percent of the pump’s rated flow. This sizing limitation exists because fire pumps are certified and tested to operate safely up to 150 percent of their rated capacity, but not beyond it. By ensuring that no connected sprinkler, monitor, hydrant, or deluge system requires more water than the pump can deliver at this upper performance limit, designers avoid conditions that would otherwise overload the pump, starve critical fire protection systems, or cause pump overheating, cavitation, or mechanical instability. For example, if the greatest fire demand is 3,000 gpm, the selected pump must be rated at least 2,000 gpm so that its 150 percent rating matches or exceeds that demand.

UL 448, the performance standard for centrifugal fire pumps, directly supports this NFPA requirement by requiring pumps to demonstrate stable, safe operation at 150 percent of their rated flow. During UL certification testing, pumps must provide at least 65 percent of rated pressure at 150 percent of rated flow while avoiding excessive vibration, overheating, or mechanical failure. Additional overload testing ensures the pump shaft, bearings, casing, and driver remain within acceptable temperature and stress limits. UL also requires stability and run-duration tests at 150 percent flow so that the pump can sustain operation at this point long enough to meet the functional needs of a fire event. These requirements confirm that pumps can safely operate at the exact limit NFPA uses as a design constraint.

FM Approval Standard 1311 contains similar performance and endurance requirements. FM requires pumps to deliver both rated flow and 150 percent of rated flow while maintaining a minimum of 65 percent of rated pressure. Pumps must also pass run testing at shutoff, 100 percent, and 150 percent capacities without overheating, exhibiting mechanical distress, or showing signs of hydraulic instability. FM adds long-duration endurance tests to verify the pump can sustain overload conditions without bearing degradation, seal failure, or fatigue cracking. These provisions reinforce the NFPA design rule by proving that approved pumps can reliably operate at the upper end of their certified performance envelope.

Together, NFPA 20, UL 448, and FM 1311 form a consistent framework: NFPA 20 dictates that system designers must limit the maximum required flow to no more than 150 percent of the pump’s rated capacity, while UL 448 and FM 1311 validate that fire pumps are physically capable of safely delivering this performance.