Reliable Source of Power for Fire Pump Systems – Based on NFPA 20

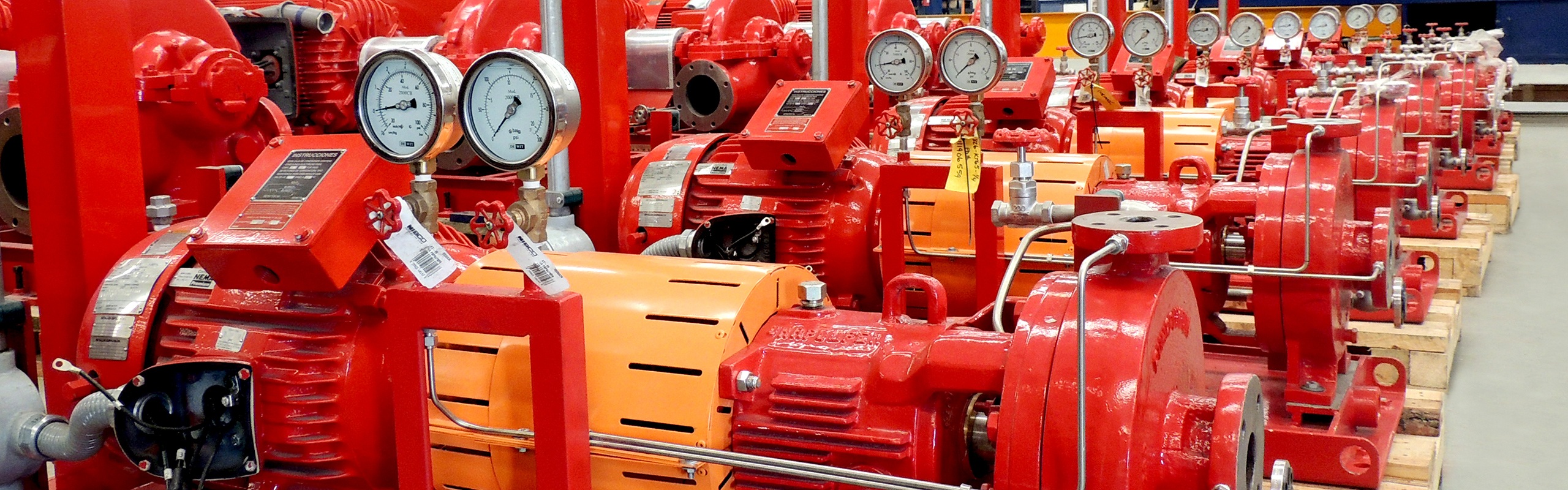

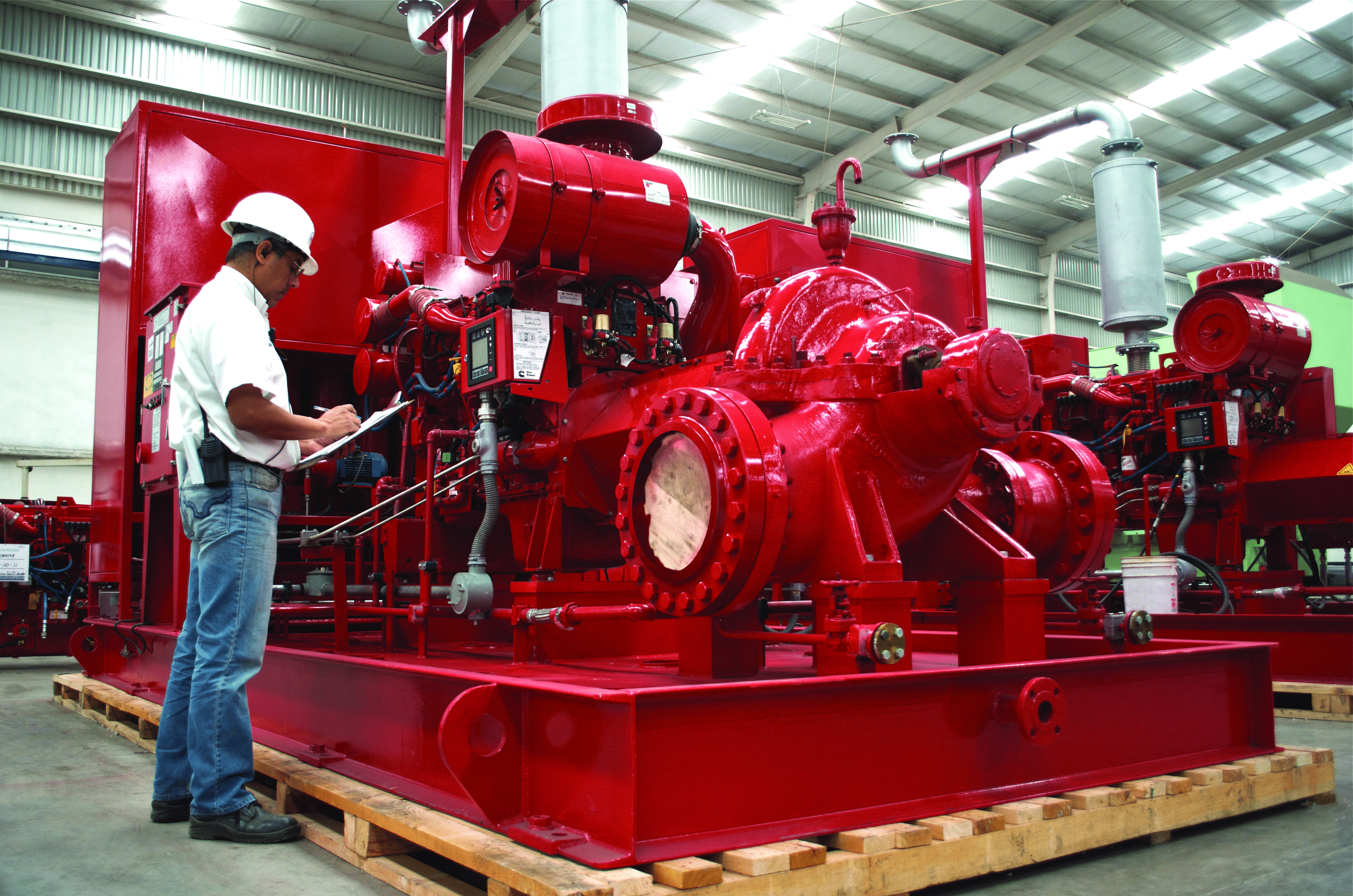

Ruhrpumpen’s Fire Campus

In previous posts, we’ve already discussed the NFPA 20 standard and its importance in the firefighting industry. In this post, we’ll dive deeper into the main guidelines and requirements set by NFPA 20 to ensure fire protection systems function properly during an emergency. We’ll also include a brief step-by-step list covering the design, installation, operation, and maintenance processes.

NFPA 20 does not provide a strict definition of a "reliable" power source within its enforceable sections. But Annex A offers important guidance often used by Authorities Having Jurisdiction (AHJs) to assess power reliability for fire pump applications.

According to this guidance, a power source is considered reliable if it meets certain criteria:

- First - The source’s power plant must not have experienced shutdowns lasting more than four continuous hours during the twelve months prior to the plan submittal.

- Second - The area or facility served by the source should not have a history of frequent unscheduled outages, with exceptions made for interruptions caused by natural disasters or large-scale utility failures.

- Third - The power supply to the fire pump should not be routed through overhead conductors located outside the protected premises, as these are more exposed to damage and fire risks.

- Finally, the system must be designed with a single disconnecting means and overcurrent protective device located at or near the fire pump controller, with no additional switches or devices that could inadvertently interrupt power to the pump.

When these conditions are not met, and the normal power source cannot be deemed reliable, NFPA 20 requires the addition of at least one alternate source of power. Acceptable alternatives include a standby or emergency generator sized to support the full starting and running load of the fire pump, a second utility service or an independent utility feed from a different substation or network path, or a backup fire pump powered by a separate engine, such as a diesel-driven pump. The purpose of these requirements is to ensure that fire pumps remain operational under all circumstances, even if the primary electrical supply fails.

In addition to evaluating the reliability of the power source, NFPA 20 outlines other important technical considerations. The system must accommodate specific voltage drop limitations. When the fire pump starts at locked rotor condition, the power system must allow for a voltage drop, typically up to 15 percent, while under full running load, the voltage drop should not exceed 5 percent. Moreover, the infrastructure supporting the electrical supply—including feeders, service conductors, and switchgear—must be carefully designed and protected. This includes placing conductors underground or in fire-rated enclosures where necessary to safeguard them from physical damage or fire exposure.

For professionals at Ruhrpumpen’s Fire Systems Division, this information has several practical implications.

First, it is important to collect and review utility performance data in every project—specifically looking for outage history and any extended shutdowns. This will help determine whether the primary power source meets NFPA’s criteria for reliability. If the utility supply is found to be insufficient, the system design must include an appropriate alternate power solution, whether through a generator, dual feed, or alternate pump type.

Early coordination with the AHJ is essential, as they have final authority in determining whether the chosen power source is acceptable. Presenting technical data and proposed alternatives during the design phase can help avoid costly delays or redesigns.

Furthermore, it is critical to ensure that all electrical components, especially disconnects and overcurrent protection devices, comply with NFPA 20’s requirements, and that overhead wiring is avoided in vulnerable areas. During system commissioning, both normal and alternate power sources should be tested under load conditions to confirm that the pump starts reliably and that voltage drops stay within permissible limits.

After installation, the power supply system must be regularly monitored and maintained. This includes routine testing of standby generators, verifying fuel availability for engine-driven pumps, and keeping detailed records of utility performance.

By following these guidelines, Ruhrpumpen can ensure that its fire protection systems meet NFPA 20 standards, providing dependable performance in emergency situations and satisfying both engineering best practices and AHJ requirements.

Are you looking for Fire Pumps and Systems to cover your pumping needs? Let Ruhrpumpen help solve your pumping demands.

Contact us now by clicking here.