Delivering High-Performance Fire Protection: Prepackaged Pump System for a Major Industrial Gases Facility in Edmonton

Ruhrpumpen's Spotlight

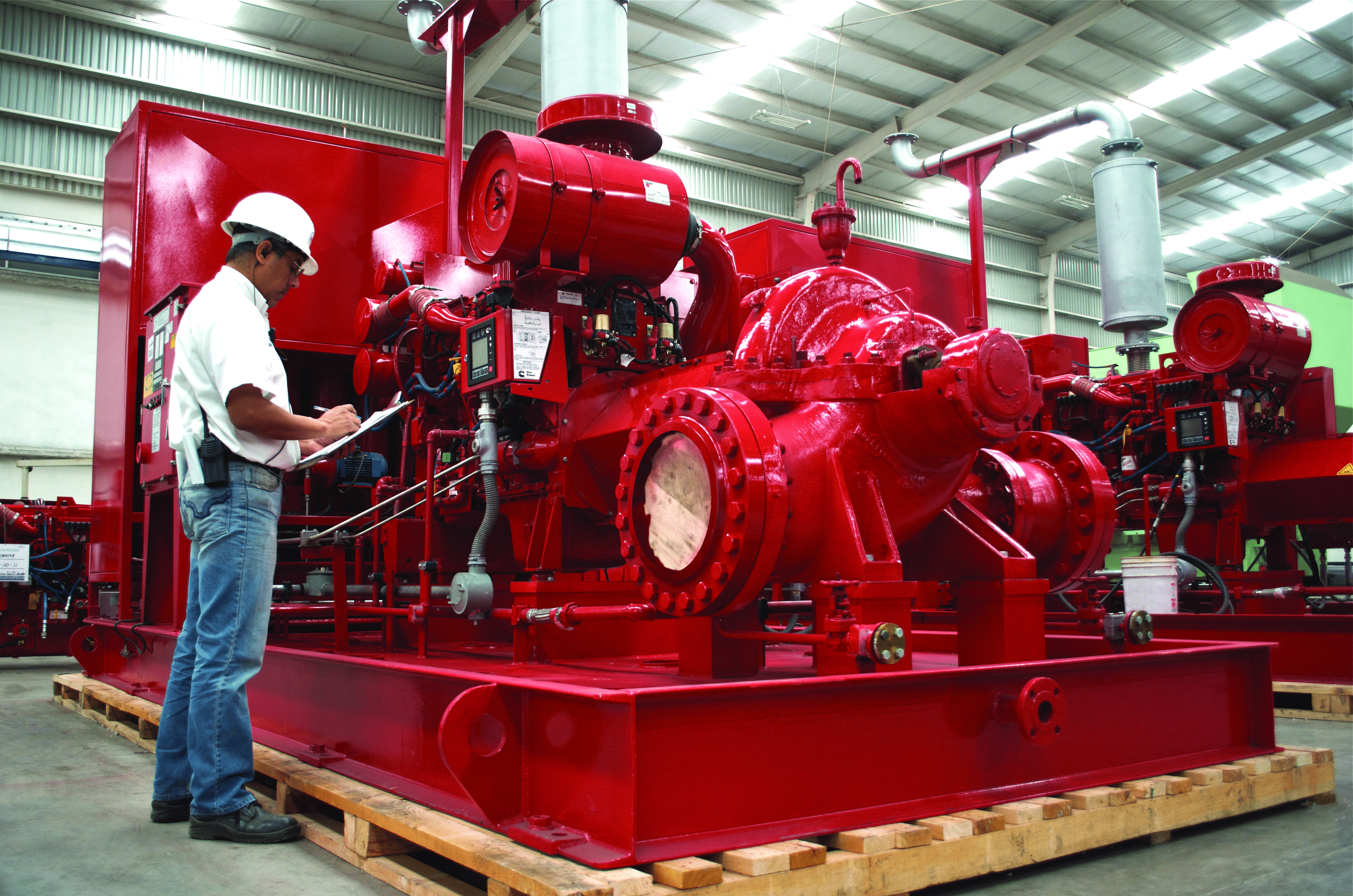

As part of its commitment to delivering reliable fire protection solutions for critical infrastructure, Ruhrpumpen’s Fire Systems Division recently completed the supply of a fully engineered, prepackaged fire pump system for a major industrial gases and chemicals facility in Edmonton, Canada. This project highlights our ability to meet demanding performance, safety, and compliance standards for world-class operations.

Engineered for High Demand Applications

At the heart of the system are two HSC 8x14x21E (E) horizontal split case fire pumps. These pumps are designed for durability, high flow rates, and reliable operation in line with NFPA 20 and international fire safety standards.

- Duty Point: 681.4 m³/h @ 106.5 m of differential head

- One pump is electric-driven, featuring:

- A 400 HP motor operating at 1800 RPM (4 poles)

- CSA-approved, suitable for CSA Safe / UL Fire Pump area classifications

- Direct-On-Line (DOL) starting method

- TEFC enclosure, with IP55 protection

- Operating at 460 V / 60 Hz / 3 phase

- The second pump is diesel engine-driven, equipped with:

- A 455 HP engine rated at 1760 RPM

- EPA Tier 3 Certified, with UL/FM approval

- 230V-AC, 2000 Watt jacket water heater for cold-weather reliability

- 24 VDC electrical system

- NEMA 4X/IP66 316 stainless steel instrument panel, ensuring corrosion resistance and system integrity

Integrated Jockey Pump for System Pressure Maintenance

To maintain system pressure and reduce pump cycling, the package includes a vertical inline multistage jockey pump, either Grundfos or Ruhrpumpen CR model:

- Flow capacity: 6.0 m³/h @ 106 meters

- ANSI 32 discharge and suction connections

- 3.7 kW electric motor at 3461 RPM, 460 V / 3 Ph / 60 Hz

- TEFC motor enclosure

- Equipped with anti-condensation heater and thermostat for extended motor life

Prepackaged Pump House

All components were delivered in a fully prepackaged fire pump house configuration, minimizing installation time and ensuring factory-assembled quality. While the specific structural details of the pump house are proprietary, this all-in-one solution includes pre-installed piping, electrical connections, and controls — greatly simplifying site integration and commissioning.

Serving a Leading Global Industrial Operator

The end user of this system is a global leader in industrial gases and chemical solutions, operating one of its key facilities in the Edmonton area. Known for supplying essential gases such as hydrogen, oxygen, and nitrogen to sectors including energy, refining, and manufacturing, this customer is recognized for its strict adherence to safety, operational uptime, and environmental standards.

Securing this project reflects Ruhrpumpen’s position as a trusted partner for high-profile industrial clients requiring dependable fire protection systems that meet exacting technical and regulatory requirements.

Are you looking for Fire Pumps and Systems to cover your pumping needs? Let Ruhrpumpen help solve your pumping demands.

Contact us now by clicking here.