HQ Vertical Circulator

Vertical Circulator Multi Stage API 610 Pumps

Vertical Circulator Multi Stage API 610 Pumps

The HQ vertical circulator multi stage pumps consist of a bowl assembly, suspended on a discharge column from a base plate at the mounting floor. The length of the column is dictated by the application.

Operation limits

Maximum Pressure 17 bar (250 psi)

Temperature up to 135 °C (275 °F)

Discharge flanges sizes 12'' to 36''

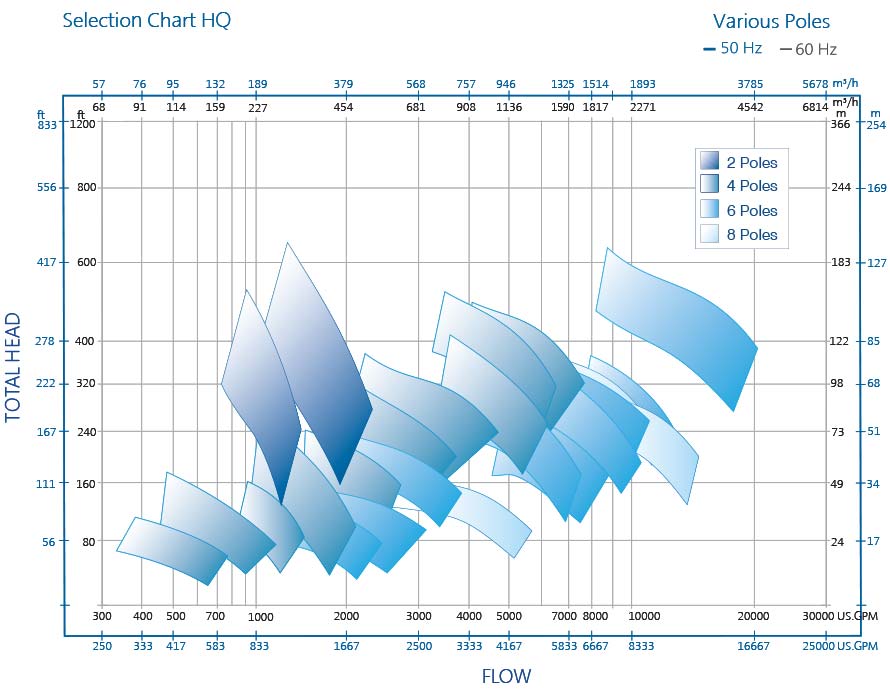

Applications Fresh water, sea water, wastewater and effluent applications, Hydrocarbons and chemicals, Cooling tower, Pipeline service, General industrial services.