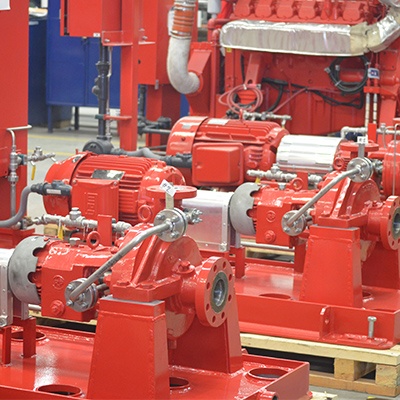

Quality, the foundation of all our operations

When customers purchase one of our pump systems, they expect an exceptional high-quality product. As a result, we are continually working to improve our processes, products, and services. We are one of the few pump companies in the world that manufactures its products in a vertically-integrated process, allowing us to deliver pump systems and components on time without ever compromising their quality.

Quality means making sure our products meet, and even exceed, our customers’ expectations. Our product development process, starts with the end user requirements in mind, understanding who they are and their needs in fluid transfer technology. Consequently, our pumps are used in heavy-duty industrial applications under the most extreme environments with great efficiency, reliability and safety.

We proudly hold the following certifications on our processes and product lines, so our customers can rest assured that their pumps and spare parts are made to the highest quality standards:

ISO 9001 Certification

Our pumps are engineered, assembled and serviced on our ISO quality certified manufacturing facilities, making them truly world-class products.

American Petroleum Institute (API)

Our complete range of API pumps meet the stringent American Petroleum Institute (API) standards for use in petroleum, chemical and gas industry services. Our API pumps can be classified by the following norms:

- API 610 for centrifugal pumps

- API 674 for reciprocating plunger pumps

- API 685 for sealless mag drive pumps

American National Standards Institute (ANSI) & American Society of Mechanical Engineers (ASME)

The American National Standard Institute (ANSI), through the American Society of Mechanical Engineers (ASME), issues minimum performance and dimensional standards for centrifugal pumps used in the chemical industry. Ruhrpumpen ANSI chemical duty pumps meet the standards as specified in the following norms:

- ANSI / ASME B73.1 for horizontal end suction, single stage, centerline discharge pumps

- ANSI / ASME B73.2 for vertical in-line centrifugal pumps for chemical process

- ANSI / ASME B73.2 for seal-less horizontal end suction pumps for chemical processes

Hydraulic Institute (HI)

The Hydraulic Institute (HI) writes product standards for the North American pump industry; they define pump products, installation, operation, performance, testing, pump life and quality. All RP pumps designed for water and wastewater applications—including those in the industrial, municipal, HVAC and fire protection—are designed in accordance with Hydraulic Institute Standards.

National Fire Protection Association (NFPA)

Ruhrpumpen Fire Protection Systems comply with the NFPA 20 standard for the installation of stationary pumps for fire protection issued by the National Fire Protection Association.

Underwriters Laboratories (UL)

Underwriters Laboratories is a global safety consulting and certification company that, among many others, evaluates and tests fire systems components (i.e. pumps, motors and engines) to determine their suitability and reliability for use in fire sprinkler systems. Ruhrpumpen Fire Pumps and Systems are designed to meet the demanding requirements of UL-448 for fire protection service.

Factory mutual (FM)

An FM approved fire pump ensures that the system’s performance characteristics meet the protection requirements. Ruhrpumpen’s fire pumps are FM Approved following a rigorous certification process to comply with the following standards:

- FM Class 1311 – for horizontal or vertical split case centrifugal fire pumps

- FM Class 1312 – for vertical shaft, turbine type fire pumps

- FM Class 1319 – for horizontal end suction centrifugal fire pumps

Innovation, turning ideas into solutions

Innovation is more than a good idea, a new technology or process. For Ruhrpumpen, innovation is part of our culture. It is finding solutions and translating discoveries to complex problems within the industries we serve.

On a fiercely competitive market, where customers demand more than standard solutions, the pump industry is facing extreme pressure on improving product efficiency. Through computer-aided design and engineering tools to create 3D models (CAD), Computational Fluid Dynamics to analyze the detailed effects of fluid flow (CFD), and Finite Element Analysis to optimize structural components of pumps (FEA), Ruhrpumpen creates energy-efficient products engineered to meet the customer’s specific design and operating performance requirements.

Our Research and Development (R&D) teams turn these ideas into business opportunities by enhancing the performance of each pump component and of the system as a whole.

Your specifications, our vast experience, in-house fabrication, engineering capabilities, state-of-the-art programs and new technologies in pump manufacturing like 3D printing, combined with our vertical integrated structure, make it certain that our pumps are fully optimized for the application requirements and are delivered in the shortest possible time.

Our vision and new tools for engineering design and manufacturing allow us to:

- Maximize pump efficiency

- Increase pump reliability

- Predict pump performance across a wide range of operating conditions

- Explore more design alternatives earlier

- Reduce costs by allowing numerous simulations

Efficiency, the key to success

In Ruhrpumpen, we continually evolve to ensure that we remain at the forefront of this exciting industry. Our efficient company structure allows us to execute short decision making processes and providing our customers with cost-effective solutions as a one-stop service supplier.

The strength of our company lies in our agility and flexibility to adapt to changing customer needs, combined with an excellent knowledge of the market, highly engineered products and agile services.

Through our Global Service Network, we support our customers with the operation and maintenance of their pump equipment, spare parts, standard overhauls and retrofit solutions, and inspections to ensure their downtime is as short as possible.

We believe that the performance of our products reflects our company’s efficiency. We are therefore experts in the continuous improvement of manufacturing processes, management systems and cost control.

Improving our operational efficiency by:

- Improving our material cost competitiveness

- Standardizing the overall quality of operations

- Capitalizing on our global presence and expanding our capacity where needed

- Increasing productivity through automation

- Developing internal processes and capabilities