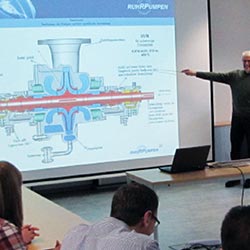

Ruhrpumpen's Technical Development Center offers a series of tailored courses focused to the pumping system market

The investment you make in your equipment is all the more profitable when it is operated safely by qualified personnel. More than 65 years of experience give us the knowledge to offer your workforce a variety of comprehensive technical pump training programs for the industry that:

- Maximize the performance of your pumping system

- Improve safety

- Reduce operating costs

- Increase your return on investment

Our world class training centers, located in Witten, Germany and in Monterrey, Mexico, together with our training teams around the globe, provide the latest computer technology, training assistance, equipment and techniques to provide cutting-edge information. Moreover, our tailored courses can be matched to the experience levels and needs of our customers in their specialized fields. This way, our team is able to provide the seminars in our training centers or tailored courses may be arranged at your facilities.

In case of customized training packages, it is possible to arrange technical practices as a complement of the theorical contents. These practices can be done in our facilities (training or service centers) or in our client's facilities. Technical practices cover field and/or engineering services such as: vibration analysis, material nondestructive examination, failure analysis and performance testing.

Centrifugal pump fundamentals training

Audience: engineers; plant operational and maintenance personnel that aim to improve their understanding of centrifugal pumps and their operation.

Objectives: to understand how centrifugal pumps work and identify the different pump types and why they're used; understand pump curves.

Topics:

- Physical principles of a centrifugal pump

- Pump systems

- Pump types

- How to operate a pump

- Main components

- Testing

- Condition monitoring

Advanced training on pump system design

Audience: engineers; plant operational and technical services personnel.

Objectives: to define and generate the ideal prototype that satisfies the needs of a pump system.

Topics:

- General layout

- Standards, codes and regulations

- Materials

- Installation requirements, external forces and moments

- Bearing concepts

- Impeller design

- Rotor-dynamics

Advanced training on pump system hydrodynamics

Audience: engineers; plant operational and technical services personnel.

Objectives: to analyze and compare physically each of the main points that intervene in a hydrodynamic system.

Topics:

- Fluid dynamics

- Specific speed

- The importance of the impeller in the system

- Volute design

- NPSH

- Cavitation

- Pump selection

- Operating systems

Advanced training on how to measure and control the vibration in centrifugal pumps

Audience: engineers; plant operational and technical services personnel who are new to vibration monitoring and analysis.

Objectives: to analyze the effects and consequences caused by misalignment and improper balancing of the elements of a pumping system through a study of mechanical vibration analysis; to find solutions and establish maintenance practices to prevent vibration.

Topics:

- Basic vibration terminology

- Vibration causes

- Consequences of vibration in a pumping equipment

- How to interpret and analyze a spectral vibration graph

- Motor-Pump assembly alignment techniques

- Predictive techniques applicable to pumps

- Condition monitoring and maintenance practices

Training on the importance and operation of fire protection pump systems

Audience: engineers; fire pump operators; plant operational and maintenance personnel.

Objectives: to identify and understand each of the elements of a fire protection system, their operation and maintenance.

Topics:

- Elements of a fire system

- Importance of the jockey pump

- Drivers and controllers

- Characteristic flow curve

- Installation requirements

- NFPA-20 standard and requirements

- Fire system inspection and maintenance

- Field testing

Other specialized courses include:

- Synergetic Retrofit

- Pump Seals

- Reciprocating Pumps (UK team)

Our Training Centers:

Germany Training Center

- Andreas Holl

Service & Training Center Manager - Stockumer Str. 28, 58453 Witten, Germany

- This email address is being protected from spambots. You need JavaScript enabled to view it.

- +49 2302 661-466

- rp_holl

Mexico Training Center

- Agustin Marroquin

Technical Development Center Manager - Niquel 9204, Parque Industrial Cd. Mitras,

Garcia, N.L. Mexico, C.P. 66000 - This email address is being protected from spambots. You need JavaScript enabled to view it.

- +52 1 (81) 8158-5500

- amarroquin44